A Plastic That Feeds the Earth, Not the Ocean 🌊

In a world struggling with plastic pollution, an extraordinary breakthrough offers hope, not only for cleaner oceans, but also for greener fields.

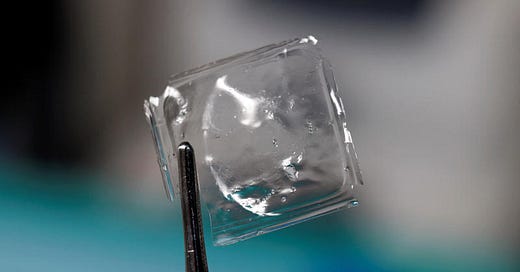

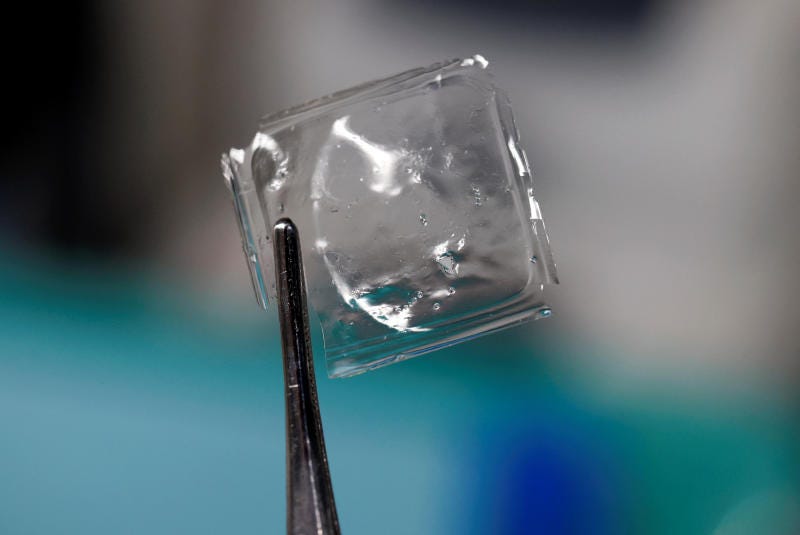

This biodegradable plastic, developed by researchers at the RIKEN Center for Emergent Matter Science and the College of Tokyo, doesn’t just disappear — it feeds.

At Logistics Insider, where we look at innovations that are reshaping sustainability and supply chain design, this new material could be a game changer for eco-smart packaging and product development.

From Waste to Fertility : A Game-Changing Material

What if the plastic you discarded today could help grow food tomorrow?

This novel plastic is made from:

Sodium hexametaphosphate (a food-safe additive)

Guanidinium-based monomers (which form salt bridges for stability)

Here’s what makes it revolutionary :

In Seawater : Dissolves within hours, leaving no microplastic residue

In Soil : Fully degrades in around 10 days, releasing phosphorus and nitrogen to improve soil health

Non-toxic, non-flammable, carbon-neutral decomposition process

This isn’t just a biodegradable plastic—it’s a bio-enriching material.

Circular Economy in Action

In a logistics ecosystem hungry for regenerative design, this material is built for reuse and environmental integration:

♻ 91% of additives and 82% of monomers are recoverable

Enables a circular economy that goes beyond waste reduction to resource regeneration

Whether it’s fishing nets, mulch films, seed coatings, or food packaging, the potential applications are wide—and impactful.

Why It Matters for Supply Chains

This innovation carries serious potential for logistics, agriculture, and marine industries:

Reduced Ocean Waste : No microplastic risk = safer marine supply chains

Fertilizer-Integrated Packaging : Perfect for agro-logistics (e.g., seed tapes, compostable mulch)

Smart Consumer Goods : Packaging that supports eco-friendly branding and decomposes cleanly

What’s Next ? Challenges to Watch

Despite the promise, the road to scale isn’t without hurdles :

🔹 Production Scale-Up : Lab success needs to meet industrial volumes.

🔹 Cost Competitiveness : Sustainable materials must match traditional plastics in pricing.

🔹 Policy & Adoption : Regulation and education will drive demand.

A Future Where Plastics Give Back

This is more than innovation, it’s a vision of plastics that heal, not harm.

Could your industry integrate bio-enhancing plastics to reduce waste and regenerate value ?

At Logistics Insider, we’ll keep tracking breakthroughs like these that challenge the status quo and redefine sustainability.

What are your thoughts ? Are your supply chain materials ready for this shift?

🚀 Follow Logistics Insider for deep dives into sustainable tech, future-ready logistics, and eco-driven product design.